Reinventing the Wheel

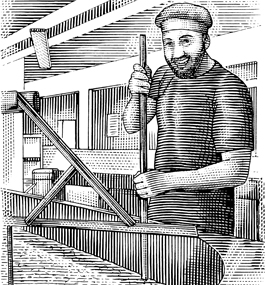

Steven Noble

by Laura Gardner

If he were alive today, Calvin Coolidge might describe the cheese being made at the 30th president’s homestead with three words: “good as ever.” Coming from the famously laconic Vermonter, such an endorsement would be sweet indeed to Jesse Werner ’02, the cheesemaker who adapted the original Coolidge family recipe as his signature product when he launched Plymouth Artisan Cheese in 2009.

More than a century earlier, in 1890, “silent Cal’s” father, John Coolidge, began making a granular curd cheese — so-called because the curds are skillfully cut and continuously stirred — in a factory he built at the family farm in Plymouth, Vt., where the president grew up doing things like scything hay and milking cows. With classic Yankee pragmatism and thrift, the elder Coolidge built the cheese factory as a way to use surplus milk in an era before timely transportation and refrigeration were available.

John Coolidge’s recipe was based on an ancient British tradition of cheesemaking that predates “cheddaring” — the process that eliminates holes and cracks in the product by stacking and milling curds to press out moisture. Plymouth cheese is similar in taste and structure to England’s famous Cheshire cheese, which dates back some 500 years.

Werner recapitulates the past by producing a tangy, semi-hard, aged cheese with notes of butter, fruit and nuts — a profile that gives it broad appeal without losing distinction. This makes it as ideal for the sophisticated palate as well as for grilled cheese lovers.

For Werner, a sociology major who grew up on a farm in the heart of the Green Mountain state’s dairy industry, the road to successful cheesemaking started with courses at the Vermont Institute for Artisan Cheese at the University of Vermont. He also earned a business degree in Prague and travelled extensively around Europe (including a junior year abroad in cheese-loving France). Werner was working in a cheesemaking operation in Quebec when he learned his home state was looking for someone to lease and operate the Coolidge homestead cheese factory.

“Plymouth cheese goes back to the time when it was named for the place where it was made, much like Grafton and Cabot cheddar cheeses,” he explains. “I wanted to revive the Coolidge family’s recipe and make it a standout cheese Vermont could be proud of.”

Werner put in a winning bid and set about adapting the Coolidge family recipes. Two years into it, he works six days per week, except in the summer, when the schedule calls for seven days. Today, the startup company makes 75,000 to 100,000 pounds of cheese annually, using raw milk from a farm in nearby Tinmouth that eschews additives, hormones and antibiotics and routinely tests for bacteria, purity and quality. In addition to Plymouth, Werner and his small staff turn out a softer, mellower product called East Meadow, along with an extra sharp Hunter and a rich smoked cheese.

“When I arrived at Brandeis and told my new friends about growing up making maple syrup, riding horses, shearing sheep, keeping chickens and, of course, skiing, they didn’t believe me — until they came to visit,” says Werner. “I knew at a very young age that Vermont was a special place. I always knew that it would be great to come back here.” But he is quick to dispel the notion that making cheese in Vermont represents some kind of idyll. “It’s tricky in Vermont,” he says, “because you have to create your own opportunities."

Werner does just that, operating a retail store on site, selling at local farmers markets, and building sales in stores and restaurants and through mail order distribution. Growing in popularity every month, the cheese is now available in Mario Batali’s Italian marketplace, Eataly, in downtown Manhattan, and a few other high-end outlets. “But we’re trying to own our own backyard, too, by getting into Vermont’s country stores and restaurants,” Werner says.

To learn more about Plymouth cheese, visit www.plymouthcheese.com.

More than a century earlier, in 1890, “silent Cal’s” father, John Coolidge, began making a granular curd cheese — so-called because the curds are skillfully cut and continuously stirred — in a factory he built at the family farm in Plymouth, Vt., where the president grew up doing things like scything hay and milking cows. With classic Yankee pragmatism and thrift, the elder Coolidge built the cheese factory as a way to use surplus milk in an era before timely transportation and refrigeration were available.

John Coolidge’s recipe was based on an ancient British tradition of cheesemaking that predates “cheddaring” — the process that eliminates holes and cracks in the product by stacking and milling curds to press out moisture. Plymouth cheese is similar in taste and structure to England’s famous Cheshire cheese, which dates back some 500 years.

Werner recapitulates the past by producing a tangy, semi-hard, aged cheese with notes of butter, fruit and nuts — a profile that gives it broad appeal without losing distinction. This makes it as ideal for the sophisticated palate as well as for grilled cheese lovers.

For Werner, a sociology major who grew up on a farm in the heart of the Green Mountain state’s dairy industry, the road to successful cheesemaking started with courses at the Vermont Institute for Artisan Cheese at the University of Vermont. He also earned a business degree in Prague and travelled extensively around Europe (including a junior year abroad in cheese-loving France). Werner was working in a cheesemaking operation in Quebec when he learned his home state was looking for someone to lease and operate the Coolidge homestead cheese factory.

“Plymouth cheese goes back to the time when it was named for the place where it was made, much like Grafton and Cabot cheddar cheeses,” he explains. “I wanted to revive the Coolidge family’s recipe and make it a standout cheese Vermont could be proud of.”

Werner put in a winning bid and set about adapting the Coolidge family recipes. Two years into it, he works six days per week, except in the summer, when the schedule calls for seven days. Today, the startup company makes 75,000 to 100,000 pounds of cheese annually, using raw milk from a farm in nearby Tinmouth that eschews additives, hormones and antibiotics and routinely tests for bacteria, purity and quality. In addition to Plymouth, Werner and his small staff turn out a softer, mellower product called East Meadow, along with an extra sharp Hunter and a rich smoked cheese.

“When I arrived at Brandeis and told my new friends about growing up making maple syrup, riding horses, shearing sheep, keeping chickens and, of course, skiing, they didn’t believe me — until they came to visit,” says Werner. “I knew at a very young age that Vermont was a special place. I always knew that it would be great to come back here.” But he is quick to dispel the notion that making cheese in Vermont represents some kind of idyll. “It’s tricky in Vermont,” he says, “because you have to create your own opportunities."

Werner does just that, operating a retail store on site, selling at local farmers markets, and building sales in stores and restaurants and through mail order distribution. Growing in popularity every month, the cheese is now available in Mario Batali’s Italian marketplace, Eataly, in downtown Manhattan, and a few other high-end outlets. “But we’re trying to own our own backyard, too, by getting into Vermont’s country stores and restaurants,” Werner says.

To learn more about Plymouth cheese, visit www.plymouthcheese.com.