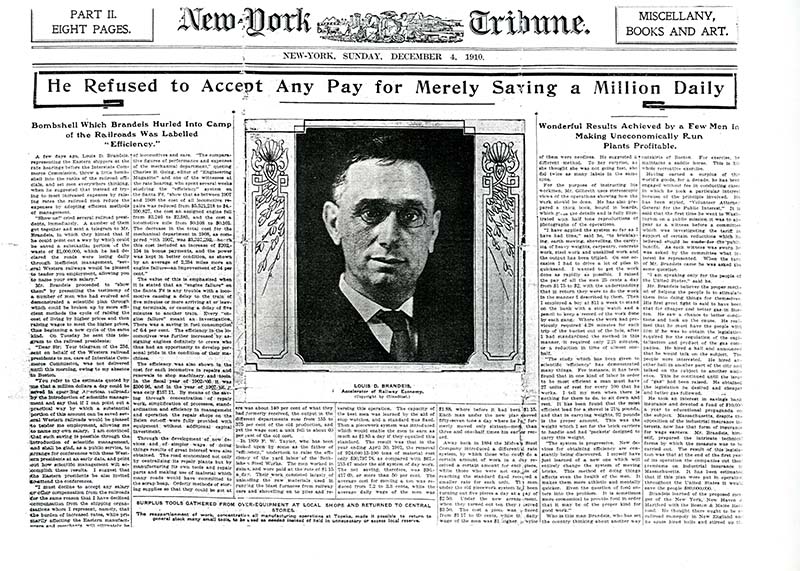

“Accelerator of the Railway Economy”

printed in the New York Tribune

Transcript

New York Tribune,

New York, Sunday, December 4, 1910

He Refused to Accept Any Pay for Merely Saving a Million Daily.

Bombshell Which Brandeis Hurled Into Camp of the Railroads Was Labelled “Efficiency.”

A few days ago Louis D. Brandeis, representing the Eastern shippers at the rate hearings before the Interstate Commerce Commission, threw a little bombshell into the ranks of the railroad officials, and set men everywhere thinking, when he suggested that instead of trying to meet increased expenses by raising rates the railroad men reduce the expenses by adopting efficient methods of management.

“Show us!” cried several railroad presidents, immediately. A number of them got together and sent a telegram to Mr. Brandeis, in which they hinted that if he could point out a way by which could be saved a substantial portion of the waste of $1,000,000, which he had declared the roads were losing daily through inefficient management, “several Western railways would be pleased to tender you employment, allowing you to name your own salary.”

Mr. Brandeis proceeded to “show them” by presenting the testimony of a number of a number of men who had evolved and demonstrated a scientific plan through which could be broken up by more efficient methods the cycle of raising the cost of living by higher prices and then raising wages to meet the higher prices, thus beginning a new cycle of the same kind. On Tuesday he sent this telegram to the railroad presidents:

“Dear Sir: Your telegram of the 23d, sent on behalf of the Western railroad presidents to me, care of Interstate Commerce Commission, was not delivered until this morning, owing to my absence in Boston. “You refer to the estimate quoted by me that a million dollars a day could be saved in operating American railroads by the introduction of scientific management and say that if I can point out a practical way by which a substantial portion of this amount can be saved several Western railroads would be pleased to tender me employment, allowing me to name my own salary. I am convinced that such saving is possible through the introduction of scientific management, and shall be glas, as a public service, to arrange for conferences with these Western presidents at an early date, and point out how scientific management will accomplish these results. I suggest that the Eastern presidents be also invited to attend the conferences.

“I must decline to accept any salary or other compensation from the railroads for the same reason that I have declined compensation from the shipping organizations whom I represent, namely, that the burden of increased rates, while primarily affecting the Eastern manufacturers and merchants will ultimately be of locomotive and cars. “The comparative figures of performance and expenses of the mechanical department,” quoting Charles B. Going, editor of “Engineering MAgazine” and one of the witnesses at the rate hearing, who spent several weeks studying the “efficiency” system on the Santa Fe, “show that as between 1907 and 1908 the cost of all locomotive repairs was reduced from $5,521,218 to $4,590,827 the cost an assigned engine fell from $3,246 to $2,585, and the cost of a locomotive mile from $0.108 to $0.101. The decrease in the total cost for the mechanical department in 1908, as compared with 1907, was $3,337,292 [illegible word] this cost included an increase of $202,154 in bonus payments, and the power was kept in better condition, as shown by an average of 2,254 miles more an engine failure--an improvement of 54 per cent.”

THe value of this is emphasized when it is stated that an “engine failure” on the Santa Fe is any trouble with a locomotive causing a delay to the train of five minutes or more arriving at or leaving terminals, or causing a delay of five minutes to another train. Every “engine failure” meant an investigation. There was a saving in fuel consumption of 6.4 per cent. The efficiency in the locomotives was further increased by assigning engines definitely to crews who thus had an opportunity to develop personal pride in the condition of their machines.

The efficiency was also shown in the cost for each locomotive in repairs and renewals to shop machinery and tools. In the fiscal year of 1902-’03 it was $306 96, and in the year of 1907-’08 it was only $157 11. By means of the saving through concentration of repair work, simplification of processes, standardization and efficiency in management and operation the repair shops on the Belen cut-off were fully provided with equipment without additional capital investment.

Through the development of new devices and of simpler ways of doing things results of great interest were also obtained. The road economized not only by centralizing its repair plants but by manufacturing its own tools and repair parts and making use of material which many roads would have committed to the scrap heap. Orderly methods of storing supplies so that they could be got at

[sections of article not present in this image]

-ers was about 140 per cent of what they had formerly received, the output in the different departments rose from 155 to 375 per cent of the old production, and yet the wage cost a unit fell to about 60 per cent of the old cost.

In 1809 F. W. Taylor, who has been looked upon by some as the father of “efficiency,” undertook to raise the efficiency of the yard labor of the Bethlehem Steel Works. The men worked in gangs, and were paid at the rate of $1 15 a day. Their work consisted largely of unloading the raw materials used in running the blast furnaces from railway cars and shovelling on to piles and reversing this operation. The capacity of the best men was learned by the aid of stop watches, and a standard was fixed. Then a piecework system was introduced which would enable the men to earn as much as $1 85 a day if they equalled this standard. The result was that in the year ending April 30, 1901, the removal of 924,0040 13-100 tons of material cost only $30,797 78, as compared with $67,-215 47 under the old system of day work. The net saving, therefore, was $36,- 417 69, or more than 50 per cent. The average cost for moving a ton was reduced from 7.2 to 3.3 cents, while the average daily wage of the men was $1 88, where before it had been $1 15. Each man under the new plan moved fifty-seven tons a day where he had formerly moved only sixteen--more than three and one-half times his earlier record.

Away back in 1884 the [Illegible] Steel Company introduced a differential rate system, by which those who could do a certain amount of work in a day received a certain amount for each piece, while those who were not capable of reaching the standard fixed received a smaller rate for each unit. The men under the old piecework system had been turning out five pieces a day at a [illegible] of $2 50. Under the new arrangement, when they turned out ten they received $3 50. The cost of piece was reduced from $1 17 to 69 cents, while the daily wage of the men was $1 higher [illegible] of them were needless. He suggested a different method. To her surprise, as she thought she was not going fast, she did twice as many labels in the same time.

For the purpose of instructing his workmen, Mr. Gilbreth uses stereoscopic views of the operations showing how the work should be done. He has also prepared a thick book, bound in boards, which gives the details and is fully illustrated with half tone reproductions of photographs of the operations.

“I have applied the system so far as I have had time,” said he, “to bricklaying, earth moving, shovelling, the carrying of heavy weights, carpentry, concrete work, steel work and unskilled work and the output has been tripled. On one occasion I had to drive a lot of piles in quicksand. I wanted to get the work done as rapidly as possible. I raised the pay of all the men 25 cents a day from $1 75 to $2, with the understanding that in return they were to do the work in the manner I described to them. Then I employed a boy at $11 a week to stand on the bank with a stop watch and a pencil to keep a record of the work done by each gang. Where the work had previously required 4.28 minutes for each trip of the bucket out of the hole, after I had standardized the method in this manner, it required only 2.21 minutes, or a reduction in time of almost one-half.

“The study which has been given to scientific ‘efficiency’ has demonstrated many things. For instance, it has been found that in one kind of albor in order to be most efficient a man must have 27 units of rest for every 100 that he works. I tell my men when there is nothing for them to do, to sit down and rest. It has been found that the most efficient load for a shovel is 21 ½ pounds, and that in carrying weights, 92 pounds is the proper amount. This was the weight which I set for the brick carriers to handle and had ‘packets’ designed to carry this weight.

“The system is progressive. New devices for obtaining efficiency are constantly being discovered. I myself have just learned of a new one which will entirely change the system of moving bricks. This method of doing things affects even the health of the men. It makes them more athletic and mentally quicker. Even the question of food enters into the problem. It is sometimes more economical to provide food in order that it may be of the proper kind for good work.”

Who is this man Brandeis, who has set the country thinking about another way outskirts of Boston. For exercise, he maintains a saddle horse. This is his whole recreative exercise.

Having earned a surplus of this world’s goods, for a decade, he has been engaged without fee in conducting cases in which he took a particular interest because of the principle involved. He has been styled, “Volunteer Attorney General for the Public Interest.” It is said that the first time he went to Washington on a public mission it was to appear as a witness before a committee which was investigating the tariff in support of certain reductions which he believed should be made for the public benefit. As each witness was sworn he was asked by the committee what interest he represented. When the turn of Mr. Brandeis came he was asked the same question.

“I am speaking only for the people of the United States,” said he.

Mr. Brandeis believes the proper method of helping the people is to stimulate them into doing things for themselves. His first great fight is said to have been for cheaper and better gas in Boston. He saw a chance to better conditions and took up the cause. He realized that he must have the people with him if he was to obtain the legislation required for the regulation of the capitalization and product of the gas companies. He hired a hall and announced that he would talk on the subject. The people were interested. He hired another hall in another part of the city and talked on the subject to another audience. This he continued until the issue of “gas” had been raised. He obtained the legislation he desired and cheaper and better gas followed.

He took an interest in savings bank insurance and devoted a fund of $10,000 a year to educational propaganda on the subject. Massachusetts, despite the opposition of the industrial insurance interests, now has that form of insurance for wage earners. Mr. Brandeis, himself, prepared the intricate technical forms by which the measure was to be carried out. The result of this legislation was that at the end of the first year of its operation the companies cut their premiums on industrial insurance in Massachusetts. It has been estimated that if this plan were put in operation throughout the United States it would save the people $80,000,000.

Brandeis learned of the proposed merger of the New York, New Haven & Hartford with the Boston & Maine Railroad. He thought there ought to be no railroad monopoly in New England and he again hired halls and stirred up th-[incomplete].

| CREATOR | New York Tribune |

|---|---|

| LOCATION | New York, New York |

| DATE | 12/04/1910 |

| FORMAT | Text (Article) |

| LANGUAGE | English |

| COLLECTION | Louis Dembitz Brandeis Collection |

| BOX, SERIES | 133, VI.I.a.1 |

| RIGHTS | Copyright restrictions may apply. For permission to copy or use this image, contact the Robert D. Farber University Archives & Special Collections Department, Brandeis University Library |