3D printing is cool and all, but at first glance, it doesn’t seem terribly relevant to International Business School graduate students until you hear Uri Kedem, MBA’18, and Ian Roy ’05 enthuse about how the technology is on the cusp of transforming business along with a host of other fields.

Kedem and seven other Brandeis students took the first-ever “Digital Fabrication with Robotics” class in Fall 2017 taught by Roy, an adjunct professor at the business school. Roy is also staff advisor to the Brandeis VR, Aviation and 3D printing clubs as well as director of the Brandeis MakerLab, where any student can learn how to scan and print 3D objects using the lab's equipment.

Kedem came to Brandeis after working at an e-commerce startup specializing in digital marketing in his native Israel. After getting interested in 3D printing and launching his own business, 3dprintingpartner.com, he applied to business schools in the U.S. while also learning about their 3D printing opportunities for students. He found the Brandeis MakerLab online and was hooked before he even got to campus.

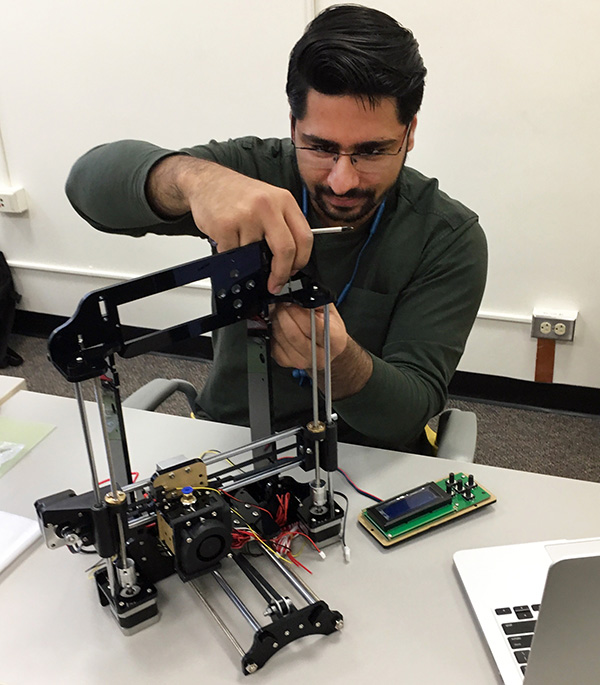

Himanshu Nagpal, MBA’19, works on assembling his 3D printer.

When he first visited the lab tucked into a corner of the Farber Library, “I saw a student from biology or chemistry printing a model of a protein molecule and an art student printing a sculpture, and I just felt like business students should be involved as well,” Kedem says.

After teaming up with Roy, Kedem helped launch the first class in Fall 2017, when eight pioneering “Brandeis Makers” assembled, calibrated and began using their own 3D printers. Students who’ve taken the class are ready to enter hackathons and use the technology to tackle real-world business challenges in case competitions.

A bookshelf in the lab displays light-hearted student creations including toys and plastic shoes (complete with plastic laces), but students also used 3D printing to make precise reproductions of sculptures and archeological artifacts, complex biomolecules and even prosthetic hands.

As the technology has gotten more sophisticated, the cost and amount of specialized knowledge required to do 3D designing and printing have plummeted. “Ten years ago, you definitely needed to be an engineer or computer scientist,” Roy said. “The tools have matured a lot. There’s a super-low barrier and a whole spectrum of off-the-shelf tools based on your learning style.” In the MakerLab, students can generate designs in a variety of ways using low-cost 3D scanning tools like XBox Kinect as well as free CAD tools and open-source 3D designs to hit the ground running.

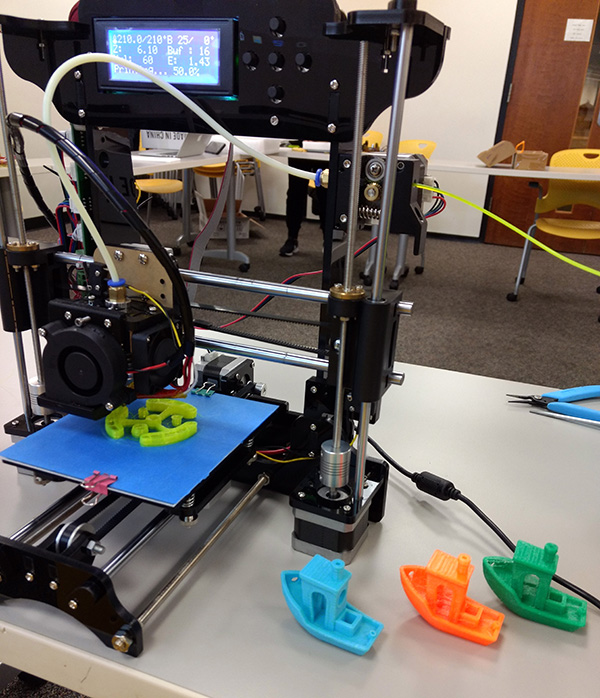

One of the 3D printers used by the Brandeis IBS students alongside some plastic boats it printed.

“A lot of MBA case studies are about how to improve the profitability of X, or acquire or merge different units. Now my perspective is wider because I can apply my knowledge in operations, marketing and entrepreneurship as I create a prototype of a product from scratch,” Kedem said. “It's the integration of two worlds.”

Adding this skill set can only help when it comes time to look for a job. “Any tech company looking for a finance person would prioritize a candidate who knows something about 3D printing and machine learning,” Kedem said.

3D printing, virtual reality, drones and other emerging technologies have implications for higher education far beyond the business and technology of product prototyping. Roy will speak on the topic at two different sessions at the EDUCAUSE Learning Initiative annual conference in late January.

“It’s about digital literacy — it’s not just designing things, but understanding what's possible in the underlying technology and then being able to communicate about it, scale it up and fund it,” Roy said.

“I hope other International Business School students will see what we’ve done with this collaboration and feel more encouraged to promote their own creative initiatives in the future, even if it takes time and effort,” Kedem said. “Now my perspective is wider because I can apply my knowledge in operations, marketing and entrepreneurship as I create a prototype of a product from scratch.”

RELATED READING (update, April 2018):

Nonprofits challenge Brandeis students to create innovative tools through 3D printing (BrandeisNOW, April 2, 2018)

Brandeis Printathon brings entrepreneurs to social justice issues" (Walthan News-Tribune, March 20, 2018)

Featured Stories

News Categories

@BrandeisBusiness Instagram

View this profile on InstagramBrandeis Intl. Business School (@brandeisbusiness) • Instagram photos and videos

August 3, 2018

The next big thing

July 31, 2018

Startups powered by STEAM

June 25, 2018

From the classroom to the boardroom